|

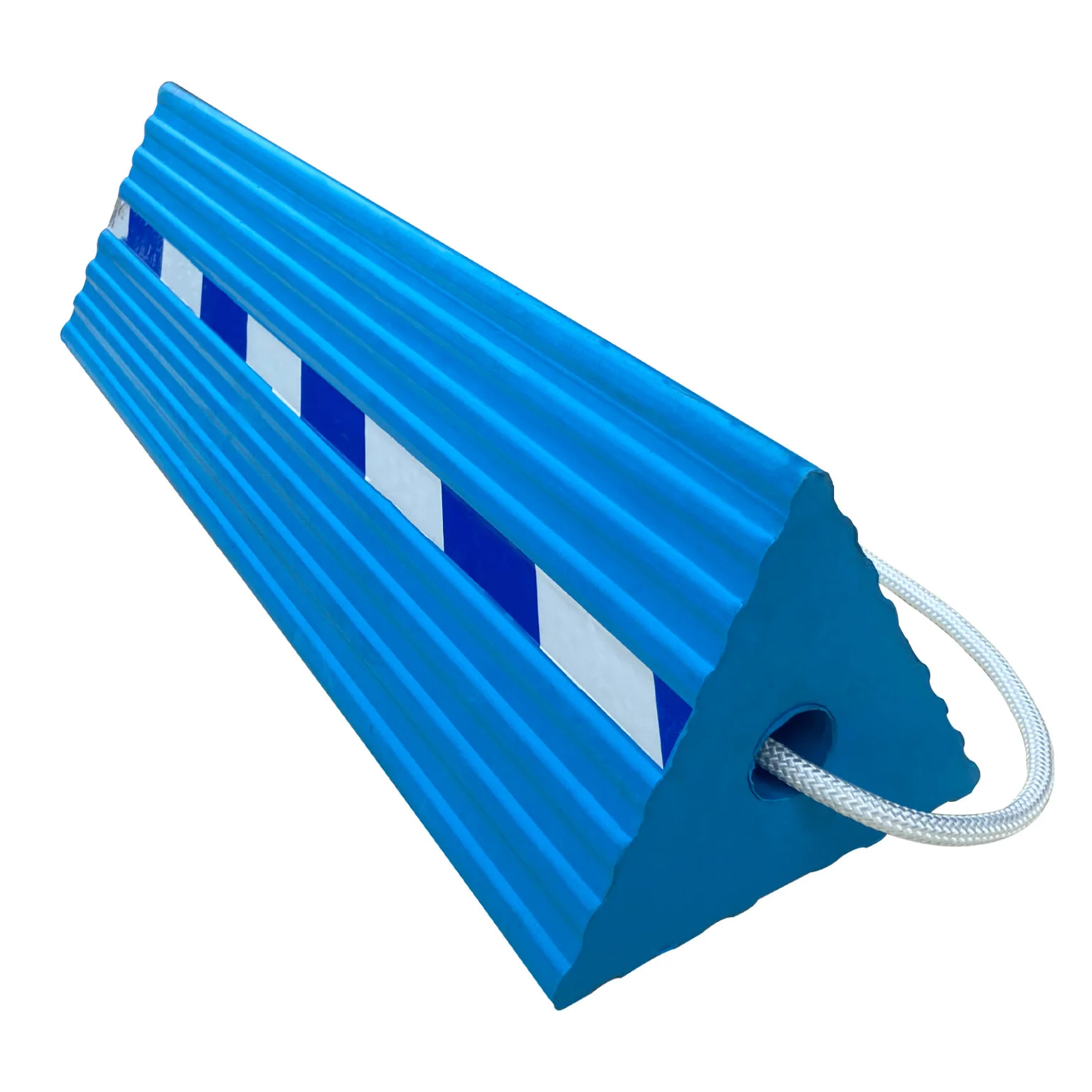

1. Limited Color Customization Reduces Visibility Most wheel chocks available in the market come in standard black or yellow. While these colors offer some level of visibility, they do not stand out against airport tarmacs, especially in snowy or low-light conditions. 🔹 Why Blue? Our client specifically requested a high-visibility blue chock to create clear contrast on wet, icy, and snowy runways while also aligning with the airport’s branding and operational zoning standards. |

|

|

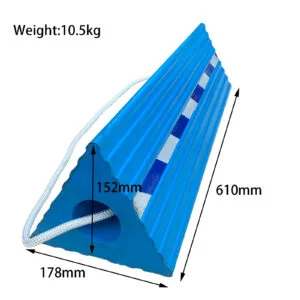

2. Inadequate Size for Larger Aircraft Standard wheel chocks in the market are often too small to effectively secure larger aircraft like Boeing 747s, cargo planes, and private jets. Smaller chocks: 🔹Struggle to prevent rolling under the weight of heavier aircraft. 🔹Require airports to use multiple chocks per wheel, increasing costs and setup time. |

|

3.Poor Performance in Extreme Canadian Weather Canada’s harsh climate—with winter temperatures reaching -40°C and summer highs exceeding 35°C—poses a challenge for many rubber materials. Many existing wheel chocks: 🔹Crack or become brittle in freezing temperatures. 🔹Deform under high heat, reducing their effectiveness. 🔹Absorb moisture, leading to reduced friction and slippage. To overcome these challenges, the airport supplier needed a custom, high-performance solution—which is why they turned to us. |

|

|

Premium Material Composition Recommended our No.1 Top Standard Rubber Material due to its superior durability, high visibility, and custom sizing options. Here’s what set us apart: /100% Natural Rubber → Unlike synthetic or recycled alternatives, our material remains flexible and strong even in extreme conditions. /High-Load Capacity → Our chocks withstand the weight of commercial aircraft, cargo planes, and heavy-duty vehicles without deformation. |

|

Custom Sizing for Maximum Security We developed an extra-large wheel chock design that provides better grip and stability for large aircraft. Using our advanced rubber processing technology, we formulated a high-density, impact-resistant material that provides superior traction on all surfaces.The increased size reduces the need for multiple chocks per wheel, saving both time and costs. |

|

Extreme Weather Resistance • Cold-Weather Tested → Remains flexible and durable at -40°C without cracking. • Heat & UV Resistant → Maintains structure and color integrity even in direct sunlight. • Moisture-Resistant → Provides superior grip in wet conditions, reducing aircraft slippage risks. The project involved a collaborative design process, extensive testing, and precision manufacturing to ensure the wheel chocks met the highest aviation safety standards. |

|

Custom Blue Color for Enhanced Visibility Optimized for snowy conditions, ensuring high contrast against white ackgrounds.Aligns with airport branding and safety zoning, making operations more organized and efficient. High visibility highly enhance the safety of larger Canande airport. |

Hot News

Hot News