Durable natural rubber base with anti-slip surface for indoor & outdoor use

Bright yellow hinged lid for easy cable installation & maximum visibility

22,000 lbs+ load capacity suitable for warehouses, events & vehicle traffic

Interlocking design for unlimited extension and large-area cable protection

Factory-direct manufacturing, OEM logo & customized sizes available

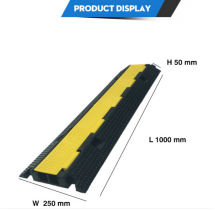

Product Overview

This Heavy Duty Rubber Cable Protector is built with industrial-grade vulcanized rubber, providing reliable protection for power cables, hoses, and fiber optic lines in both indoor and outdoor applications. The textured surface enhances traction, while the bright yellow lid improves visibility and safety in busy areas.

Product Dimensions (Adjustable):

Overall Size: 1000 × 250 × 50 mm

Channel Size: 35 × 35 mm (2 Channels)

Weight: 5.5 kg / pc

Load Capacity: 20,000–22,000 lbs

As a factory + trading integrated manufacturer, we support full customization, including size, color, logo, accessories, and private label packaging.

Product Size Chart (Multiple Models)

Channel Ramp Production Steps

step 1 – Rubber Vulcanization by Machine

The production begins by placing pre-mixed high-strength rubber compound into precision steel molds.

After vulcanization, skilled workers manually trim off excess flash and remove unwanted rubber around the edges.

precision trimming ensures smooth edges and accurate lock positions.

Guarantees proper fit and seamless assembly in later steps.

Each piece is visually inspected to eliminate surface defects or molding imperfections.

This step ensures excellent appearance quality and assembly accuracy.

Step 2 – Manual Trimming of Excess Rubber

After vulcanization, skilled workers manually trim off excess flash and remove unwanted rubber around the edges.

Precision trimming ensures smooth edges and accurate lock positions.

Guarantees proper fit and seamless assembly in later steps.

Each piece is visually inspected to eliminate surface defects or molding imperfections.

This step ensures excellent appearance quality and assembly accuracy.

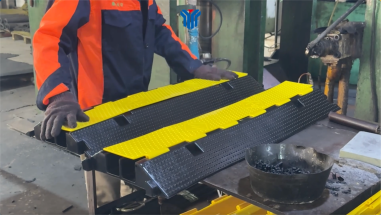

Step 3 – Placement of the Yellow Safety Cover

The yellow high-visibility safety cover (PU/PVC material depending on model) is positioned and locked onto the ramp base.

The bright yellow surface complies with safety visibility standards.

Each locking point is checked to ensure the cover engages securely.

Smooth opening and closing is tested to confirm long-term usability.

At this stage, the ramp gains its protective cover and safety warning function.

Step 4 – Finishing with Rubber Dot Cap & Final QC

Rubber dot caps are installed to reinforce cover stability and enhance the surface’s anti-slip performance.

A full Final Quality Control (QC) inspection is carried out:

Cover opening/closing test

Load-bearing simulation test

Surface defect inspection

Dimensional accuracy and fitting check

Only products that meet export-level standards are approved for packing and shipment.

Through these four strict steps, the finished product offers:

20,000–22,000 lbs load capacity (depending on model)

High impact resistance and long-term durability

UV-resistant, weatherproof, and suitable for all outdoor environments

High-visibility yellow cover for safety awareness

Ideal for industrial sites, warehouses, events, and vehicle traffic areas

20+ years of rubber & traffic safety manufacturing experience

In-house molding, vulcanization, and testing capability

Flexible MOQ with stable lead time

Direct factory pricing with no middleman

Professional export team providing global support